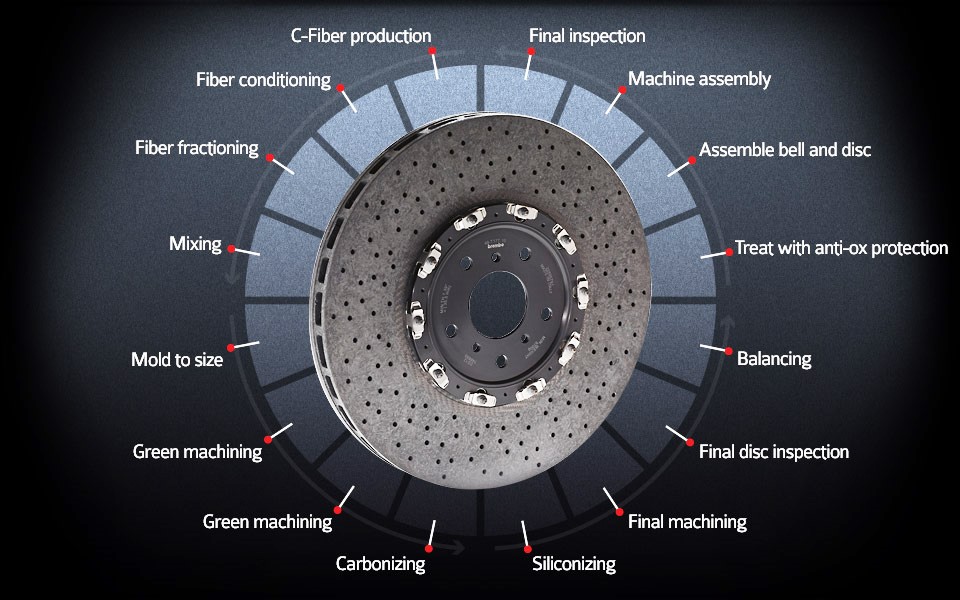

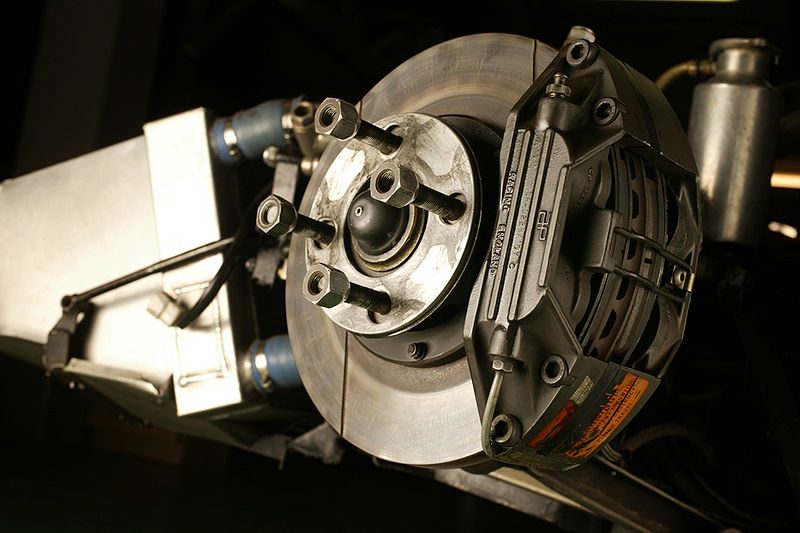

Silicon resin is shot through with small grains of carbon fiber and moulded into the shape of a brake disc with regular holes added radially to create cooling vents.

Ceramic brake disc material.

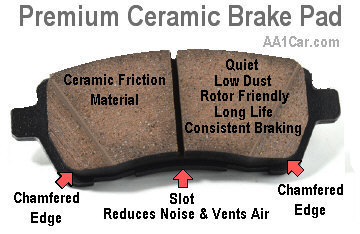

These pads are very durable and smooth gripping capability.

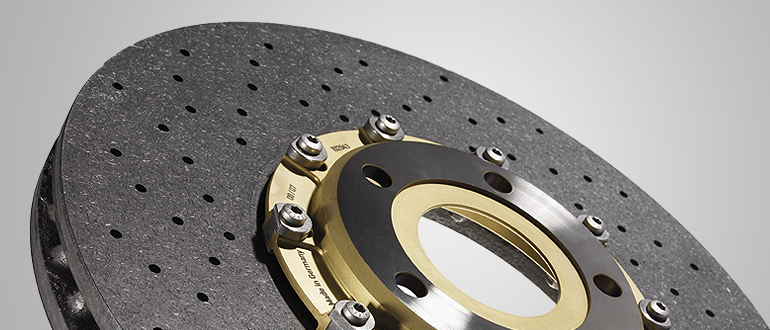

Material a special feature of the carbon ceramic brake discs is represented by the ceramic composite material.

So like their metallic counterparts they do use metal parts but the main material is ceramic.

This is a super quiet pad.

This material is obtained through a particular process which gives the possibility to add or deposit a layer of material to improve the friction coefficient on both the braking surfaces.

High performance minimum weight.

Developed in the 1980s ceramic brake pads area blend of super strong ceramic think of it a bit like pottery fired in a kiln with copper fibers embedded into the pad compound.

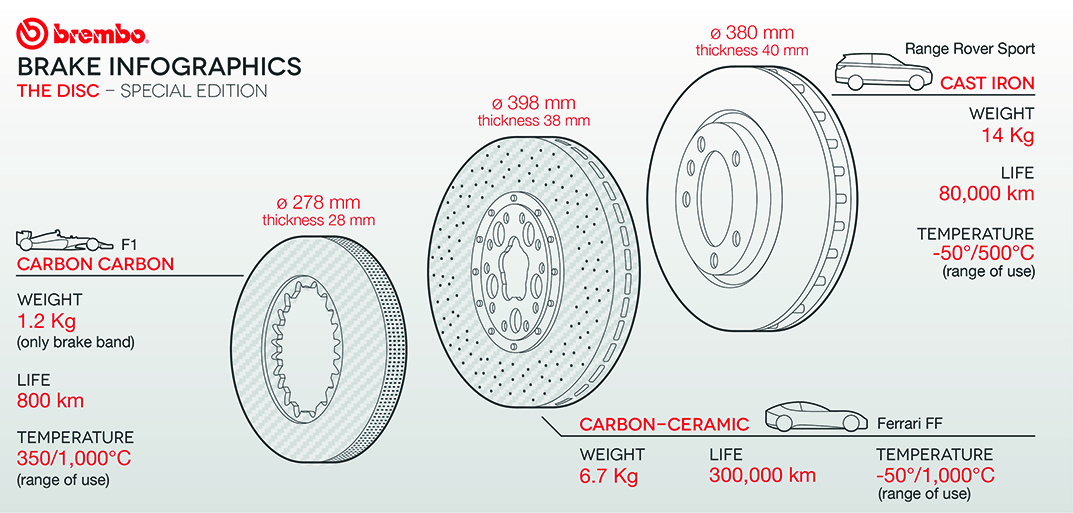

Rather than cast iron or steel carbon ceramic brake discs are made from a composite material.

This high performance material made from a special mixture of powders resins and fibres in a complex manufacturing process has been used since the 1970s in braking systems for aerospace applications and since the 1980s in motorsports.

The ceramic materials are the composition of porcelain and clay.

Ceramics are nonorganic nonmetallic substances created by the action of heating and cooling to form a crystalline structure.

The brembo group has been manufacturing carbon ceramic discs for automotive applications since 2002 when it first supplied these components for the ferrari enzo.