It s a cleaner that will best keep your manifold looking new.

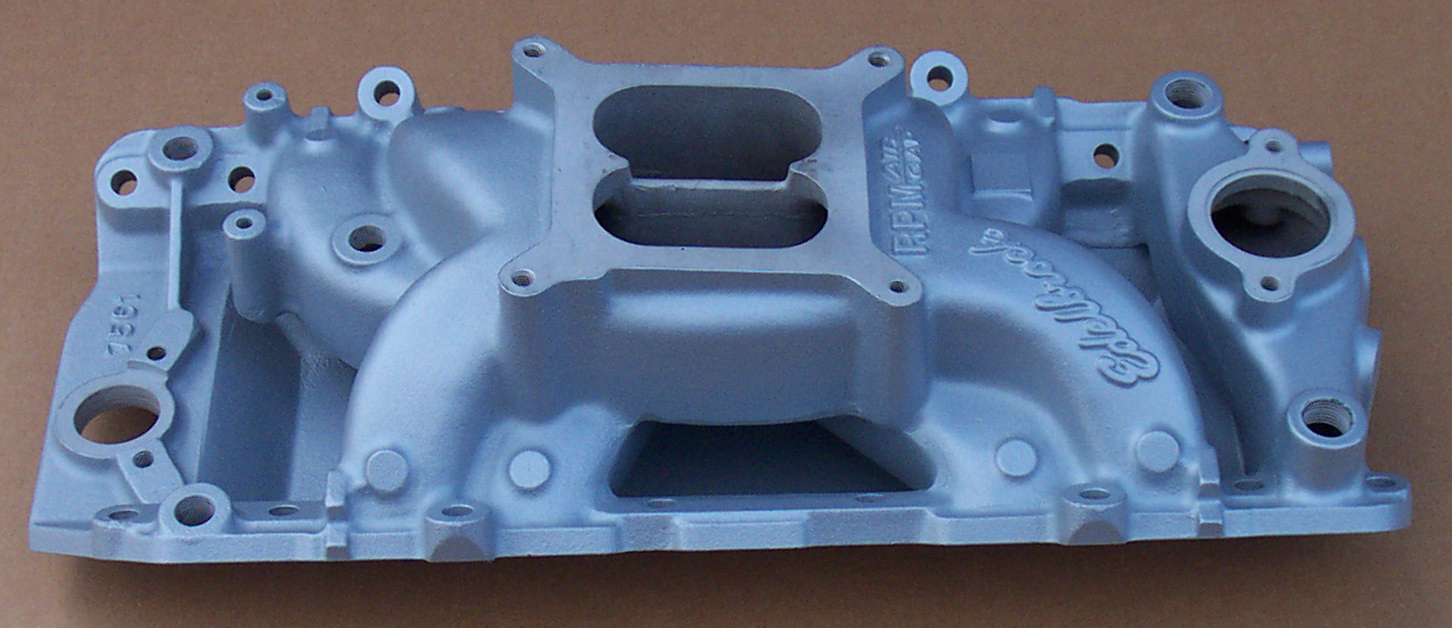

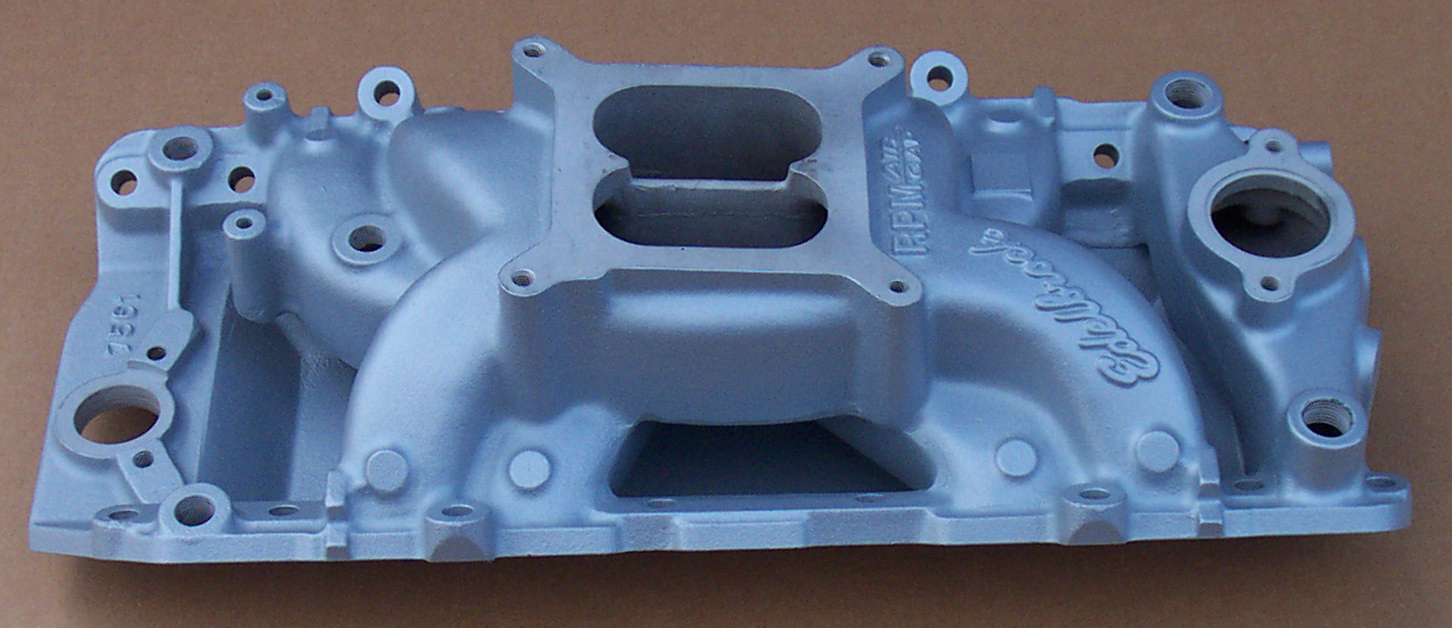

Ceramic coating aluminum intake manifold.

The first would be performance the second appearance.

Ceramic header coatings by jet hot improve the look and performance of your vehicle by reducing heat and corrosion.

Coating an intake manifold v8 v6.

Exhaust manifold coated with ceramic coating that is both a thermal barrier and corrosion resistant exhaust manifolds can either be a cast iron factory type manifold or a tube steel header typically used in performance applications though they are becoming very common in oem applications.

There are two reasons for coating an intake manifold.

You will also acquire heat from the hot oil that may be tossed up under the underside of.

This would include pistons aluminum cylinder heads aluminum rocker arms intake manifolds turbo intake housings shock absorbers trailing arms and aluminum cylinder sleeves aluminum sprockets to name just a few.

Let s discuss performance first.

Learn why industry leaders recommend that you get your vehicle jet hotted.

Trying to prevent oxidation on a new intake by putting a few layers of clear coat enamel on it.

Intake manifolds intakes are coated on the bottom with the oil shedding coating to cut thermal transfer from the oil to the intake charge.

The outside surface of intake manifolds can either be coated with our cermachrome polished aluminum look or if extreme heat is a problem our thermal dispersant coating.

In this instance you are dealing with heat that is generated by the engine.

13th part of the oldsmobile 455 marine engine build.

Zybar coating can be applied to both the inside and outside of steel stainless cast chrome or aluminum exhaust system components to provide increased corrosion protection and heat management.

We have all the resources you ll need to do it yourself.

Zybar is the first high performance high temperature coating you can apply yourself.

A solution as mentioned is to have it powder coated eastwood sells a cast aluminum looking powdercoat.