Was founded in 1969 to develop and supply high quality titanate ceramic powder formulations to the ceramic capacitor industry.

Ceramic dielectric powder.

Pdc was founded in 1990 as the first local manufacturer and exporter of ceramic dielectric powders and multilayer ceramic chip capacitors in taiwan.

Tpl offers a range of titanate powders with controlled size and chemistry.

The cog ceramic powder is for microwave application that has high q low esr at high frequency.

Less demanding applications such as impedance matching or tuning will benefit from the application specific ceramic materials which can be provided in custom shapes such as bars substrates or powders for dispersion into polymers.

The micropower technologies division dielectric constant.

Pdc provides full lines of dielectrics powder along with below good specialty for disc type capacitor mlcc type capacitor and patch antenna resonator filter applications.

Pdc allied with psa group in september 2005 and officially merged with frontier in 2008.

Ferro manufacturers a large array of dielectric ceramic powders and formulations specially designed to deliver high performance in many non capacitor components.

These include high frequency dielectric powders low temperature ceramic formulations and new ceramic formulations for microwave 5g applications.

Ferro is a leading supplier and formulator of class ii x7r dielectric powders designed for use in the manufacture of class ii multilayer ceramic capacitors mlcc and single layer capacitors slc as well as for electronic ceramic devices where x7r class ii tcc temperature coefficient of capacitance characteristics are required.

This feature allows the mlcc can be used in cellular phone communication device microwave amplifier blue tooth module computer etc.

Pdc ceramic dielectric powder ranks in no.

Advanced capacitance materials primarily for electromagnetic weapon systems and is a manufacturer of nano size ceramic dielectric powders monolithic ceramic capacitors and substrates as well as specialty dielectric materials.

Class 2 ceramic capacitors have a dielectric with a high permittivity and therefore a better volumetric efficiency than class 1 capacitors but lower accuracy and stability.

Dimat s management team has over eighty years of experience in ceramics technology.

2 in global capacity and no.

3 in global market share.

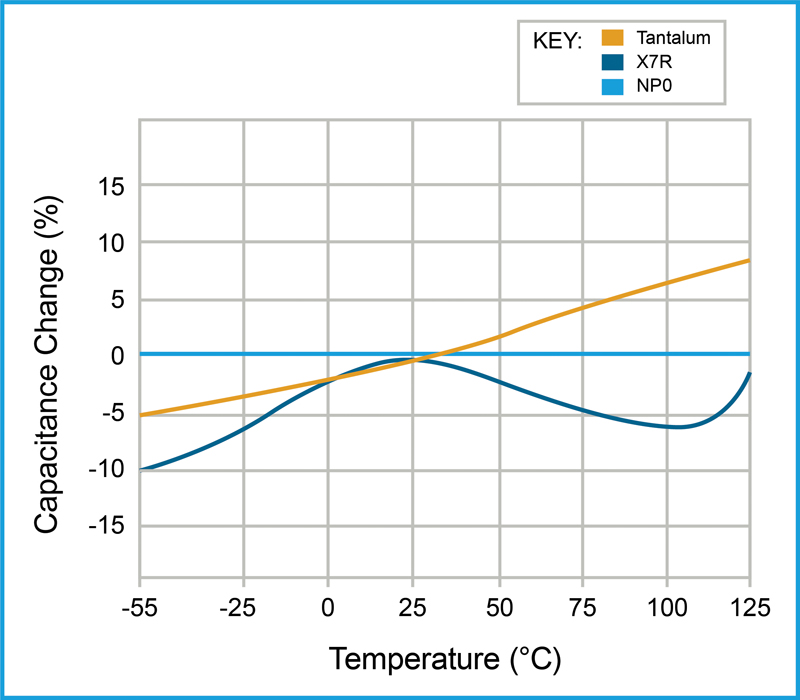

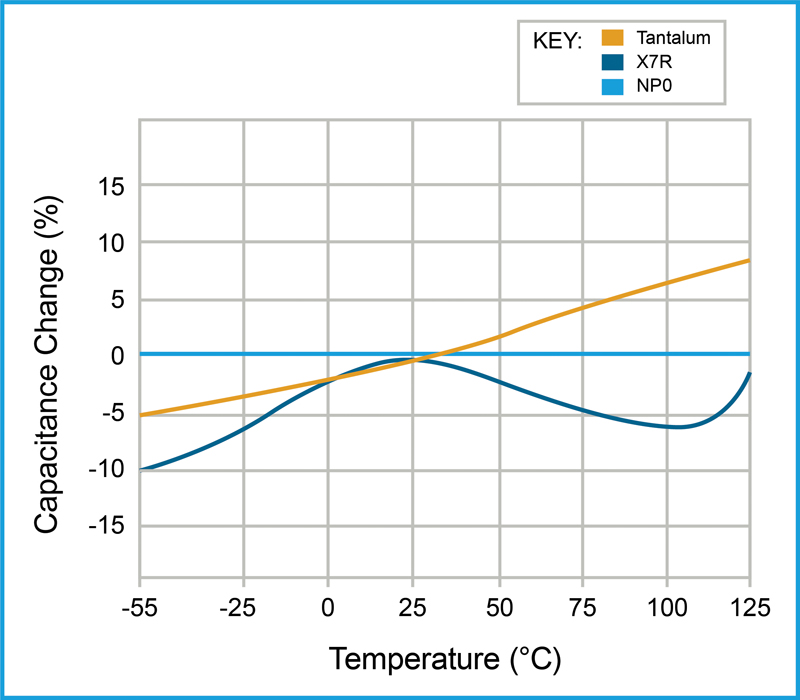

The ceramic dielectric is characterized by a nonlinear change of capacitance over the temperature range.

Tpl has the ability to provide ceramic nano powder formulations to customer specifications.

X7r formulation has very fine grain size and density structure.

The capacitance value also depends on the applied voltage.

The ultra fine particle size 50 to 400 nanometers nm of these ceramic powders make them ideal for ultra thin dielectric layers in composites and ceramic capacitors.