The developer s product manager matthieu guillon recommended a starting speed of 825 sfm up to 3 300 sfm 250 to 1000 m min and feed rates starting at around 0 001 ipt 0 03 mm depending on the tool.

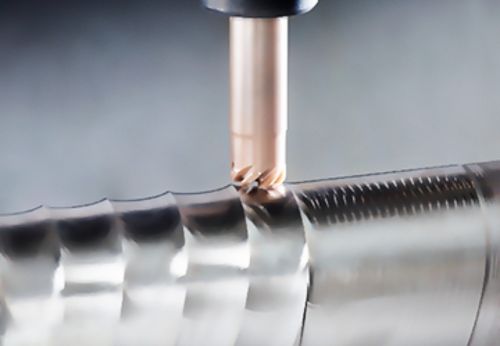

Ceramic end mill inconel.

The end mill is made from sialon kys40 grade ceramic and designed specifically for roughing in nickel based high temperature alloys.

It s time to upgrade from carbide to this unique sx9 si.

The increased use of very hard materials accounts for part of the reason why the use of ceramic end mills is increasing mr.

Application grade ød c flute cutting speed sfm feed ipt depth of cut a p inch width of cut a e inch coolant.

Nickel based high temperature alloys such as inconel were formerly used only for a narrow range of aerospace related parts.

Mitsubishi materials solid ceramic corner radius end mills are designed for roughing thru semi finishing of nickel based heat resistant alloys hrsa like inconel 718 and are available in 4.

Optimum ceramic grade selected for high speed machining at high temperatures with roughing efficiency surpassing carbide end mills.