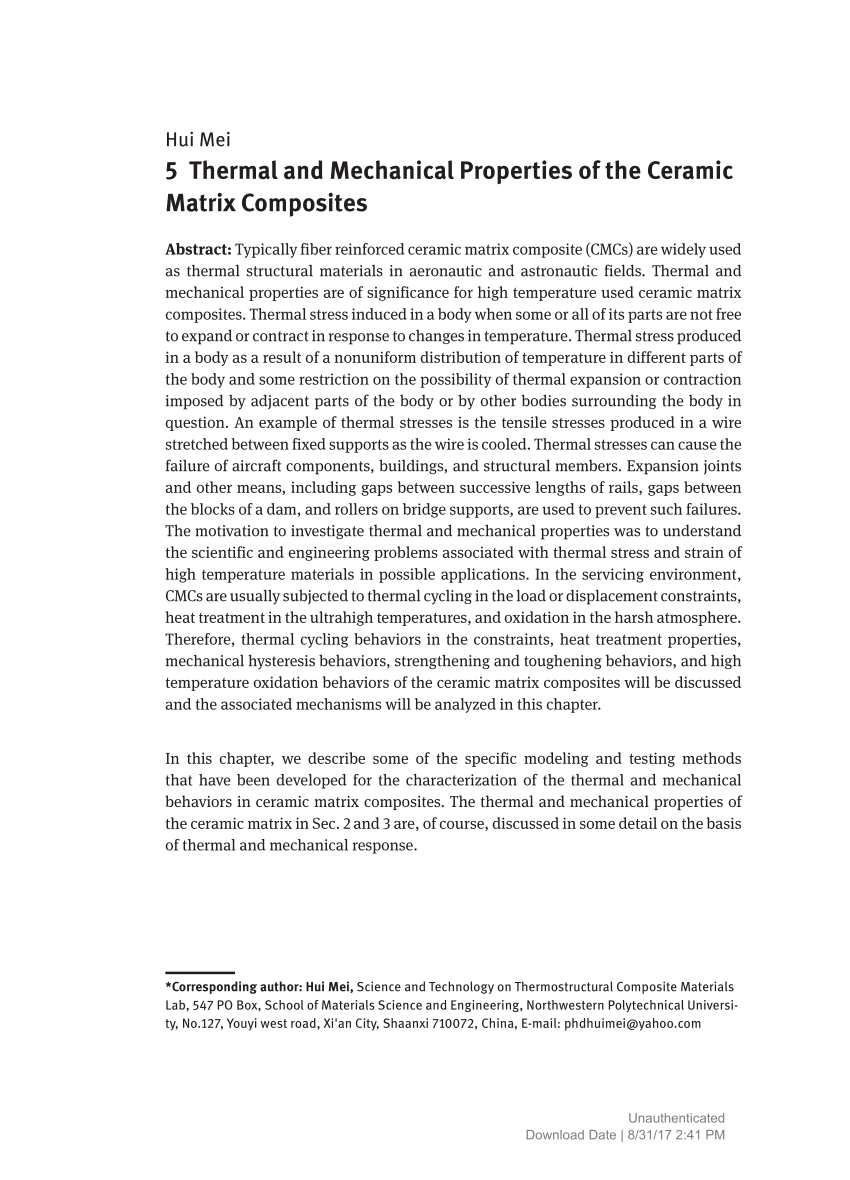

Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

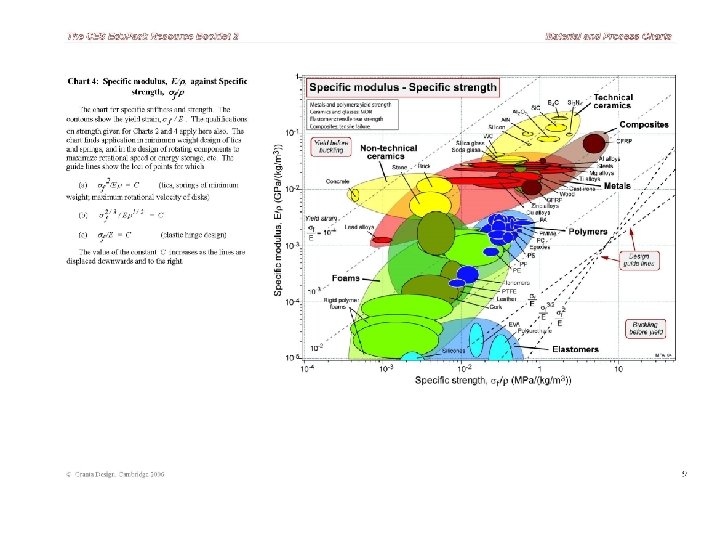

Ceramic matrix specific modulus.

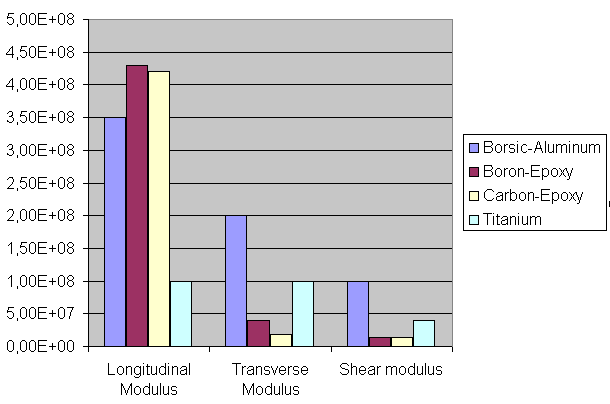

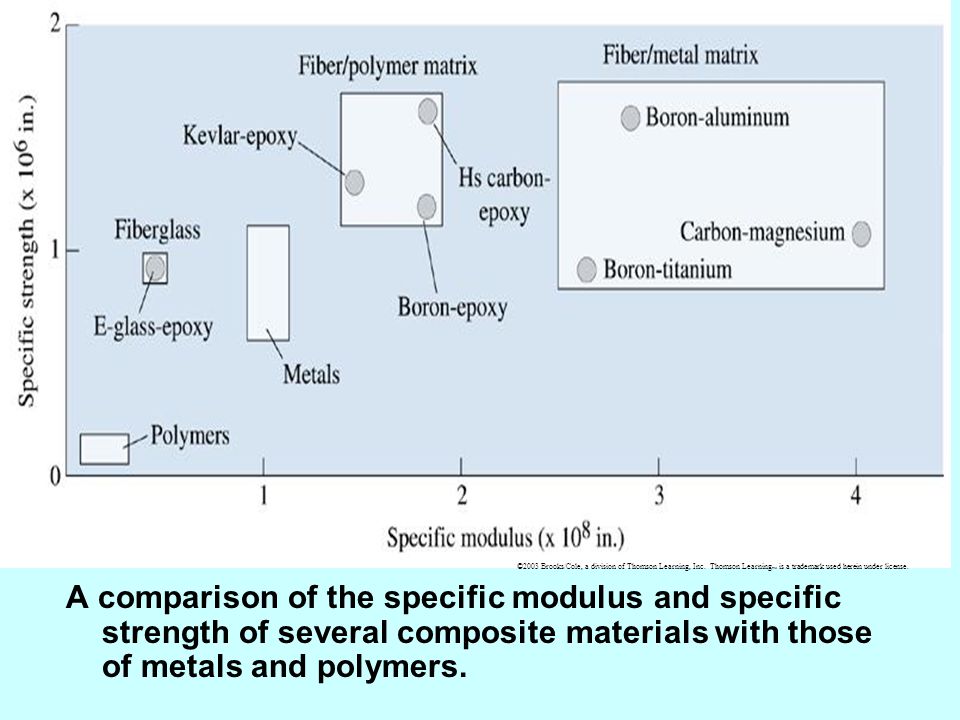

Specific modulus is a materials property consisting of the elastic modulus per mass density of a material.

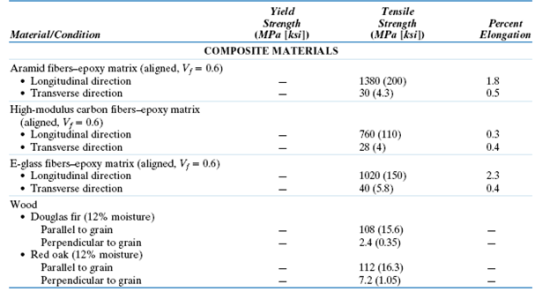

While the data in these charts is in most cases typical of what you will find from ceramic component suppliers it is only intended to be a general point of reference and should not be used for material selection or specification.

Tungsten carbide chemical formula.

We have collected a number of charts detailing applications and properties for some of the most commonly used ceramic materials.

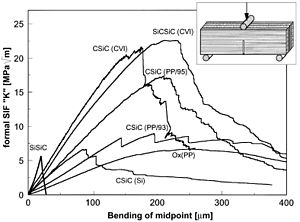

Ceramic matrix composites cmcs have the advantages of low density high specific strength high specific modulus and high temperature resistance etc and are the candidate materials for the hot section components of aerospace vehicles high.

Durability of ceramic matrix composites presents the latest information on these high temperature structural materials and their outstanding advantages over more conventional materials including their high specific strength high specific modulus high temperature resistance and good thermal stability.

Graphenes with a high young s modulus strength and large specific area are well dispersed in the ceramic matrix transferring the load from the matrix which notably improves the composite flexural strength 42 46.

The critical nature of the application of these advanced materials makes it necessary to.

Ceramic matrix composites cmcs have become an important material for the hot end parts of new generation aero engines with a high thrust weight ratio because of their high specific strength high specific modulus high temperature resistance and oxidation resistance in the actual service environment cmcs are susceptible to fatigue loading due to the fluctuation of.

Wc is a chemical compound specifically a carbide containing equal parts of tungsten and carbon atoms.

In its most basic form tungsten carbide is a fine gray powder but it can be pressed and formed into shapes through a process called sintering for use in industrial machinery cutting tools abrasives armor piercing shells and jewellery.

The critical nature of the application of.

Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material.

The dimensional analysis yields units of.

It is also known as the stiffness to weight ratio or specific stiffness high specific modulus materials find wide application in aerospace applications where minimum structural weight is required.

Specific modulus last updated september 29 2019.

Durability of ceramic matrix composites presents the latest information on these high temperature structural materials and their outstanding advantages over more conventional materials including their high specific strength high specific modulus high temperature resistance and good thermal stability.