Ceramic elements produced by ceramicx include ceramic trough elements ceramic hollow elements ceramic flat elements and ceramic infrared bulbs.

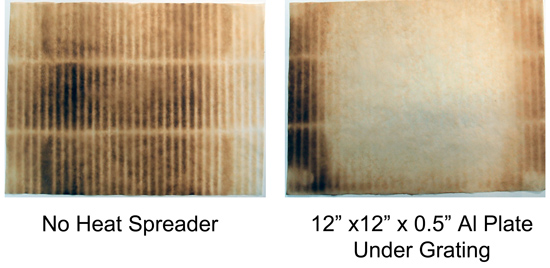

Ceramic infrared element uneven heating.

Pans with thicker bases often provide the most even heat.

These ceramic bulbs provide the infrared heat required without any of the negative effects of a light output that can disturb the day night sleeping cycle of the reptile animal.

Applications almost anywhere a non contact heat source is needed including heating curing cooking and drying though ceramic the elements are fairly rugged and are more durable than quartz and cleaning is easy with their splash proof non corrosive glazed finish which also makes them the ideal choice for use in food handling medical facilities or other antiseptic applications.

Our range of ceramic heater elements can be used in a wide range of commercial and industrial processes.

But they re equally as effectual when used as heating in any paint curing.

Mor infrared ft 1000 240 frk l6 y 0 ceramic infrared heating element with cast in type k thermocouple 240 volt 1000 watt yellow glaze 9 65 inches long x 2 36 inches wide 64 88 64.

Heat storm infrared elements are made of tungsten or carbon fiber.

Mor infrared ft 1000 240 0 l6 wh 0 ceramic infrared heating element for industrial processing applications 240 volt 1000 watt white glaze 9 65 inches long x 2 36 inches wide 40 88 40.

Their long wave infrared radiant heat is highly effective in heat applications including thermoforming packaging and annealing.

Ceramicx hollow cast bulbs consist of a high temperature fecral resistance alloy embedded in a specially formulated ceramic body allowing operating temperature up to 530 c and a maximum power of 400w esexl model only.

Because of this it can take a long time for ceramic systems to take effect.

Quartz infrared elements in order to emit significant amounts of infrared light enough to be consid ered an infrared heater an element must be heated to 1600 degrees fahrenheit.

Nichrome the material used in most heaters would melt at those temperatures.

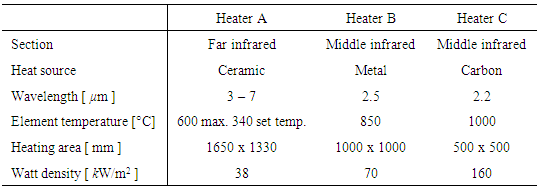

Ceramic elements have a temperature range of 300 c to 730 c and produces an infrared wave of 2 10 µ.

88 get it as soon as wed oct 7.

Ceramic infrared heating elements.

These elements are manufactured by moulding a resistive conductor into a ceramic mass.

Ceramic coated pans and stainless steel are more likely to heat food unevenly and may leave marks on the range s surface as well.

They do not directly heat your skin but instead increase the temperature of the space around you leading to a warmer environment over time.

Ceramic units tend to be very simple featuring a heating element and a fan to disperse the hot air.

Ceramic infrared heating elements are used for hardening and drying processes among others.