So the membrane replacement component of the opex is then approximately proportional to the ratio of the membrane cost l to the net flux j times the membrane life t.

Ceramic membrane vs polymeric membrane.

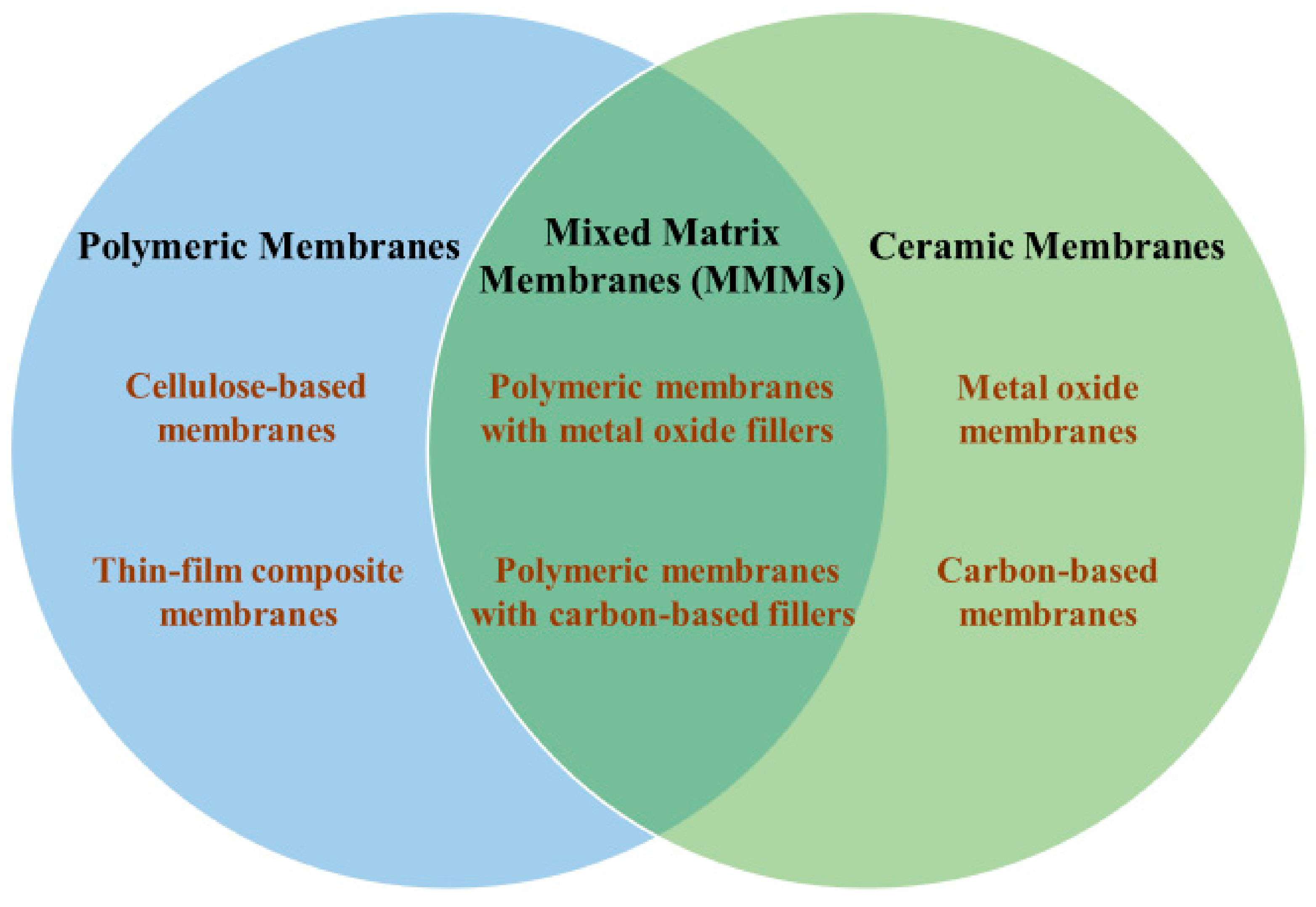

A number of different polymeric and ceramic materials are used to form membranes.

The downside of ceramic membranes is the high sensitivity to temperature gradient which leads to membrane cracking.

The higher degree of fouling on the polymeric membrane is partly due to its lower volume area ratio compared to ceramic membranes.

They are generally used for highly acidic or basic environments due to inertness.

Moreover chemical cleaning efficacy on membrane fouling of polymeric membrane 24 25 and ceramic membrane 26 27 has only been studied in isolation with disparate initial fouling extent and different cleaning protocols.

This makes these membranes suitable for many applications where polymeric and other inorganic membranes cannot be used.

The trans membrane pressure tmp increase at a constant flux of 150 l m 2 h 1 due to membrane fouling by direct filtration with lake water is investigated for four ceramic al 2 o 3 zro 2 tio 2 sic and a pes pvp polymeric microfiltration membrane s the membrane structures and compositions are characterised with permporometry pore size porosity and xps.

Additionally ceramic membranes are ideal for in place chemical cleaning at high temperatures while using caustic chlorine hydrogen peroxide ozone and strong inorganic acids and or by using steam sterilization.

To be made useful the membrane material must be formed or configured in such a way as to allow water to pass through it.

The type of membrane used in an application is dependent on waste characteristics treatment objectives and the best economic solution for the plant.

Opex l j t this means that as far as the cost effectiveness of the ceramic membrane compared with the polymeric one is concerned the determining factor is the ratio of the term l j t for the two materials.

There are mainly two different types of membrane material.

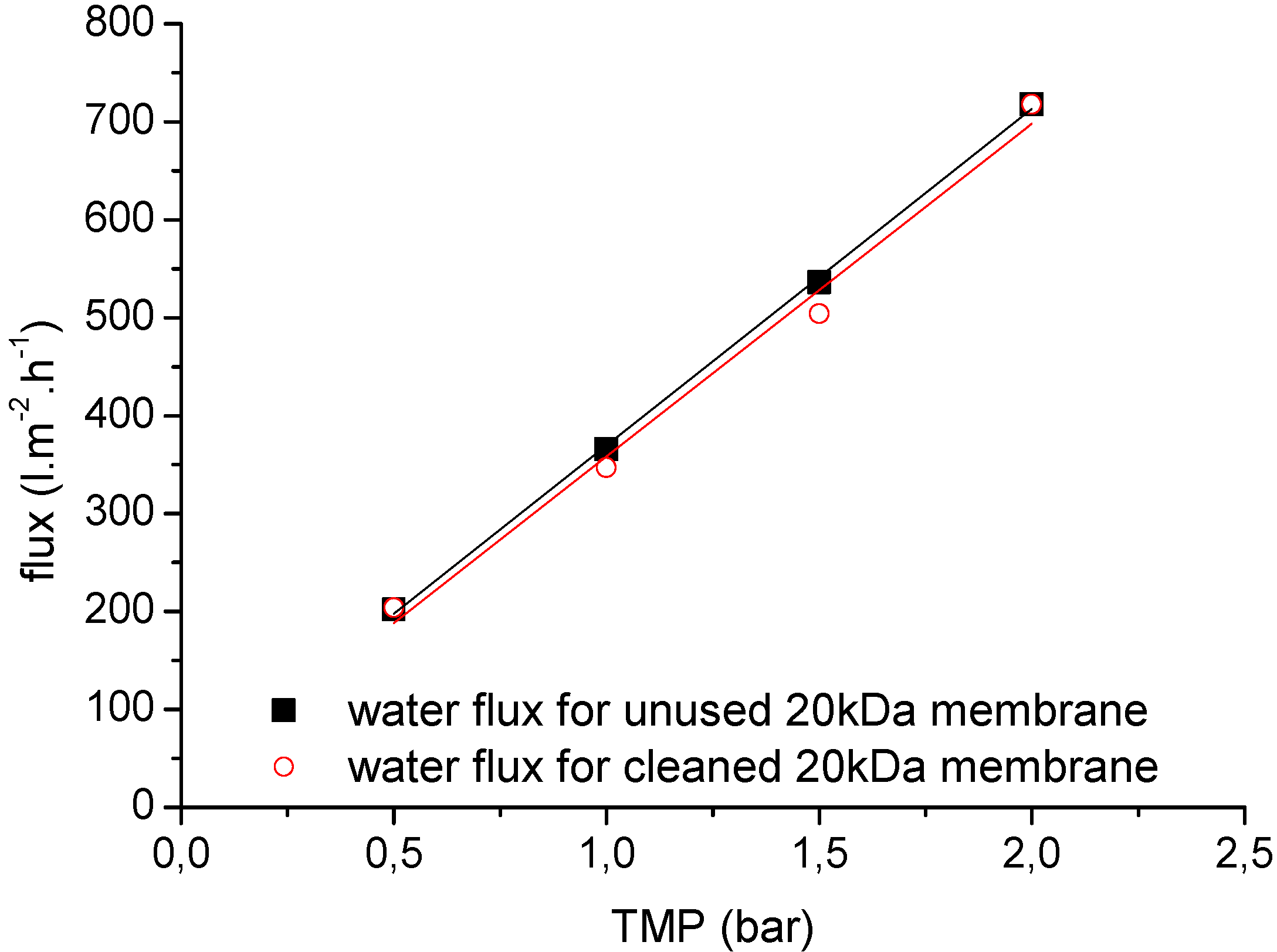

Comparison of polymeric and ceramic ultrafiltration membranes 129 0 2 4 6 8 10 12 14 5 1030 1550 300 membrane cut off kda permeate flux m 3 m 2 d c pes polymeric membranes ceramic membranes fig.

Consequently cleaning effect on membrane fouling is lack of comparability between polymeric and ceramic membrane.

Polymeric and ceramic membranes aqua aerobic systems provides two types of aqua multibore membranes polymeric and ceramic.

Distilled water flux for polymeric and ceramic membranes a similar dependence as that for distilled water was observed for all the mem.